Waterproof

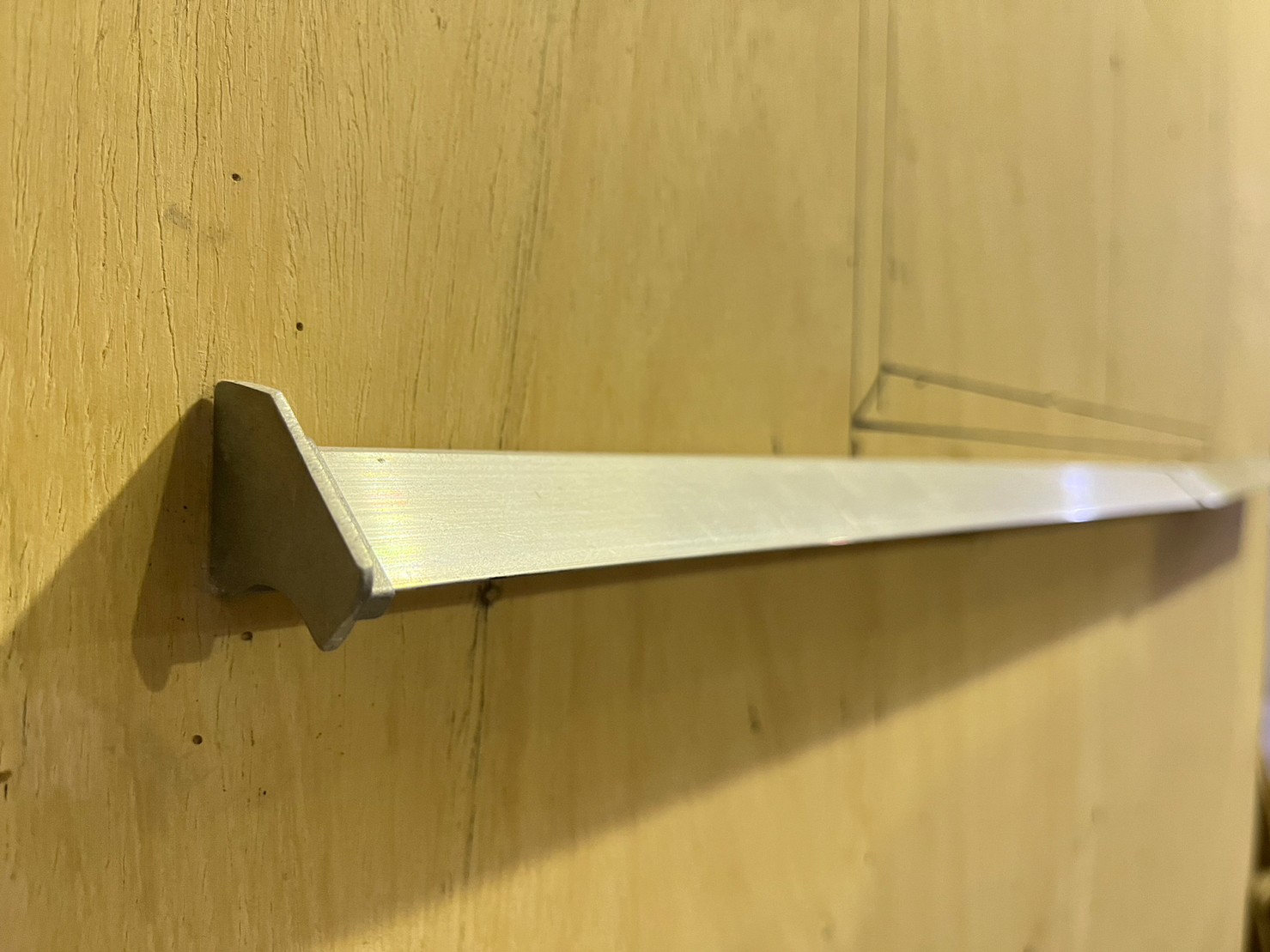

Drip edges are a kind of building material used outdoors. Because dust and dirt are easily generated on the building plane, after being washed by rainwater, it is a product derived from leaving water stains and dirt on the wall.

Drainage, discharge rainwater, and break the path that flows down the roof wall. After installation, the sewage is cut off by the clean water line, and cannot touch the wall to achieve anti-fouling, beautiful and waterproof effects.

Drip bar features

Reduce the cost of building materials

Save on facade maintenance costs

Maintain builder quality

Changbao Building has a beautiful appearance

Decorate and highlight the building facade lines

Drip bar effect

Prevent dirty water marks

reduce mural cancer

reduce water seepage

Drainage, water cutting, destroying the path of rainwater and dew

flowing down the roof and wall, and draining the rainwater.

scope of use

Installed at the junction of building facades and planes such as balconies, window frames, wall tops, roofs, and window eaves.

The occurrence of wall cancer indicates that there is a high probability of moisture in the building structure. If you only scrape off the surface whitewash, the roots of the mold are still in the wall. Coupled with the moisture source in the wall, wall cancer will still appear over time. Generally, DIY waterproofing at home is a surface waterproofing or beautification operation, which does not cover the methods of solving the cause of leakage and strengthening the structure.

The cause of wall cancer is that water penetrates into the wall and the calcium, magnesium, potassium and other salts in the cement react to form hydroxides. Under the influence of temperature and humidity, the hydroxides seep out of the concrete surface through capillary tension and then react with carbon dioxide in the air to form white carbonate crystals.

Blooming and wall cancer are common problems in buildings, and their formation is mainly related to water vapor infiltration. White bloom is a white salt attachment that is precipitated as the water evaporates after the soluble components in materials such as concrete and bricks dissolve in water. It is commonly seen on cement-painted walls, affecting the appearance and causing the cement paint to peel off. White bloom can be divided into three types: dry, wet and crystalline salt. Dry white bloom is powdery or filamentous, wet white bloom forms white water flow marks, and crystalline salt is composed of soluble salts such as sulfates or chlorides, which may come from mixing materials or infiltration of polluted water.

Wall cancer is caused by long-term moisture inside the building. The water reacts chemically with the salts in the cement to produce hydroxides, which seep out of the concrete surface through capillary action and then combine with carbon dioxide in the air to form white crystals.

If wall cancer is not treated for a long time, it will not only affect the building structure, but also cause steel corrosion, reduce the life of the building, and even breed mold due to the humid environment, causing harm to human health, such as causing respiratory diseases such as asthma or allergic rhinitis.

The force and angle of the water removal are very important factors. Improper operation can easily cause structural damage. The thickness of the waterproof layer and the matching materials are also very important. Use it in the right place, the base material of the building itself, and the space. DIY products provide quick and easy home repairs. Leakage repair problems should be left to professional leak detection experts!

1. Removal: remove the surface wall brick or cement paint, and the damaged building body structure.

2. Base surface finishing: clean up the dust, sundries, debris, etc. that have been removed.

3. Water cut-off: find out the water leakage and seepage point, and remove it.

4. Structural strengthening: strengthen the damaged structure.

5. Waterproof layer: primer and waterproof coating

6. Water test: Test whether there is any water leakage in the waterproof layer.

7. Backfill: fill back the cement and make a good discharge slope, so there will be no water accumulation problem.

Waterproofing on the frontside: the side that comes into contact with water.

For underground structures, waterproofing on the frontside involves constructing a waterproof layer on the exterior surface of the underground building. After the structure is backfilled, the water and soil pressure in the ground directly acts on the waterproof layer.

Waterproofing on the backside involves designing and constructing a waterproof barrier on the interior surface of the structure. For a water storage tank, waterproofing on the backside means the waterproof layer is located on the exterior surface of the structure.

For example:

For example, on the exterior wall of a basement, groundwater tends to seep in from the outside; the exterior is the waterproof side.

For example, on a pool, water tends to seep outward; the interior of the pool wall is the waterproof side, and the exterior is the waterproof side.

Waterproofing starts with physical fitness, and the bottom surface itself is a waterproof material, reducing the chance of being damaged

Traditional waterproof materials form a layer of waterproof film on the surface of concrete to prevent the intrusion of water, which belongs to the outer layer of waterproofing; while the waterproofing mechanism of Mapebe is to integrate with the cement structure and improve the watertightness of concrete, blocking the internal capillary The holes belong to the inner waterproofing.

Through the special structural strengthening technology, it has the characteristics of waterproof, strong adhesion, high density, secondary impermeability, breathability, protection of the structure, leakage repair, good water permeability, strong adhesion, low water absorption, and good impermeability. Heavy metal, suitable for general construction and engineering use.

feature

Material: This product is made of powder, special waterproof material, aggregate and retarded methyl fiber.

Construction scope: One-time construction for interior and exterior walls can reduce costs

Multi-function: Durable, waterproof, can be constructed according to different tools and methods to form different effects.

Material collocation: This product can be used with cement and sand, and has anti-negative pressure performance.

1. The mixed chain of pure inorganic special raw materials can be completely combined with the same properties as concrete and cement base materials. Enhanced adhesion, excellent durability.

2. Excellent inorganic material, resulting in an ultra-low water absorption rate of 0.14%, which is a must. It has excellent waterproof and can be constructed in water. Moisture-proof, alkali-resistant, frost-resistant, anti-moisture, and suppress white blooms.

3. Penetrate into the wall and combine with cement

4. Enhance interface integration

5. Improve organizational structure

Convenient construction

The construction method, proportion and habits are the same as ordinary cement, easy to use.

Fast construction and good adhesion: it can be directly applied to the cement base surface

Short setting time: good workability, reduce working hours

Add Meibibao to water and stir, let it stand for the chemical reaction, then apply it to the required ground or negative water surface, and apply it on the ground or wall when it is slightly wet for maintenance. After maintenance, you can apply another paint.

Different from general waterproof materials, it has a good effect on negative water pressure. It can penetrate deeply and react with free calcium in concrete to produce insoluble crystals to fill capillary pores.

Application steps

Preparation tools: Meibibao, health tape, empty bucket, brush, trowel, sandpaper, stirring stick

1. Base surface cleaning: use health tape for peripheral protection

2. Scraping the damaged basal surface of the wall cancer

3. Use sandpaper to polish the base surface

4. Add water to Mabibo to make a paste, the ratio is (Mabibo 2: water 1), stir and let stand for five minutes

5. Apply Maple on the wall

6. Sprinkle water for 3 days

Make a teaching video:

https://www.medusa-paint.com.tw/show-234530.html

[White Phenomenon]

The hydration product of concrete, calcium hydroxide Ca(OH)2, is a highly soluble substance and is easily dissolved in water (especially when the water contains carbon dioxide). The dissolved substances can be separated out of the structure, resulting in the so-called "white bloom" phenomenon.

Penetrating crystalline material is a surface inorganic filler, bonded to an acrylic inorganic resin using a small amount of resin. It is suitable for interior and exterior wall coatings to enhance waterproofing.

It strengthens the interfacial bonding between materials. The active chemicals in the penetrating crystalline waterproofing react with the concrete, penetrating into the concrete to form a waterproof membrane. Penetrating crystalline material can be applied to the concrete surface.

1. Features

|

Features |

Easy, one-swipe application for excellent waterproofing results Quick and easy application, no hammering required |

|

Tools |

Spray gun, roller, brush |

|

Applications |

Building interior and exterior walls, sculptures, three-dimensional objects, office buildings, commercial spaces, etc. |

|

Base Surfaces |

Cement, tiles, washed gravel, etc. |

|

How to Use |

Dilute with water and mix. Easy to use, even for first-time users. |

2. Performance

1. Water-based waterproof material, environmentally friendly

2. Easy application for excellent waterproofing

3. Quick and easy application, no hammering required

4. Applicable to any material

5. Non-toxic, odorless, and safe to apply

3. Learn more

https://www.medusa-paint.com.tw/permeated-crystal-material.html

Using the concept of physical waterproofing, waterproof particles are evenly distributed throughout the material being added. Even cross-sections are filled with waterproof particles, preventing penetration into cracks.

1. Waterproofing starts with the foundation.

2. Highly durable, the inorganic Ai Waterproof has a lifespan almost as long as cement.

3. It saves time and effort; it can be used as a wall primer, effectively waterproofing the surface.

4. Environmentally friendly, non-toxic, and non-volatile, it does not affect residential health.

1. Features

Ai Waterproof is a liquid additive. Once mixed with cement or mortar, it forms a solid foundation for wall waterproofing.

It can also be used as an additive in tile adhesives and wall repair and filling materials.

It withstands positive water pressure without affecting application. It can be used in cement primers, tile adhesives, tile caulking, stone washing, stone maintenance, etc.

It is easy to apply, and the liquid mixes evenly, resulting in excellent waterproofing performance. It is a safe, non-toxic, and odorless waterproofing formula suitable as a cement additive.

2. Usage

Add iWaterproof to cement mortar as water to create a waterproof base coat. It can also be added to tile grout, adhesives, and more.

3. Performance

● Highly Effective Waterproofing: Excellent waterproofing performance

● Non-toxic and Safe: Mildew-resistant and moisture-barrier, beneficial to residential health

● Good Adhesion: Excellent adhesion, forming an integral part of the base material

● Liquid Waterproofing: Plant-based liquid waterproofing, co-works with cement, reduces labor by 50%, withstands positive and negative water pressure, and prevents whitening

Related Information:

Simply put, the differences between organic and inorganic compounds are:

1. Organic compounds are derived from living organisms, while inorganic compounds must be produced by living cells.

2. Inorganic compounds are derived from minerals or rocks.

1. Features

Traditional waterproofing methods are like a "raincoat," with a layer of waterproofing material applied on the outside. However, over time, the waterproofing layer becomes brittle and detaches due to prolonged exposure to sunlight and rain. Inorganic crystal mineral thermal insulation waterproofing material penetrates into concrete, bonds with it, and absorbs it, blocking the pores and preventing moisture from entering. This provides excellent waterproofing and thermal insulation properties.

|

Features |

Designed for roof renovation and new roof waterproofing projects, this waterproofing and thermal insulation product effectively reduces temperatures by up to 16 degrees Celsius. It's easy to apply and weather-resistant. |

|

Tools |

Specialized spray gun, trowel, pressure tank, air compressor, etc. |

|

Applications |

Roofing, exterior walls, tile renovation and leveling, tile caulking, etc. |

2. Process

|

First coat |

High-adhesion interface primer |

|

Second coat |

Inorganic crystal thermal insulation waterproofing material |

|

Third coat |

Inorganic crystal thermal insulation waterproofing material |

|

Fourth coat |

Waterproof protective topcoat |

3. Performance

1. Environmentally friendly, safe, and easy to apply.

2. Waterproof, crack-resistant, heat-insulating, and cooling, effectively reducing temperatures by up to 16 degrees.

3. Fast application, shortening construction time. Can be sprayed or troweled.

4. Highly self-cleaning, dust-resistant, and easy to clean. Surface dirt can be easily removed with water.

5. Waterproof and moisture-proof, with excellent stain resistance.

6. Excellent weather resistance.

7. No need for cleaning.

8. Lightweight, reducing the load on buildings, and excellent adhesion.

https://www.medusa-paint.com.tw/waterproofed-and-heat-insulation-inorganic-crystals.html